Sanitary Process Hoses

Sentinel Process Systems is your one-stop shop for sanitary process hose assemblies made for an extensive range of different applications. Our team does all the work. We’ll research the products you need and source a cost-effective solution. We also offer stocking services to simplify inventory controls and help prevent material outages.

Sanitary Flex Hose Solutions

Our catalog features products made from multiple base materials. We also offer rapid custom fabrication for tubing in the lengths you need with the fittings you require. Every hose we distribute is serialized for simplified inventory management, and custom tagging services are available.

High Purity Hose Assemblies

Our high purity sanitary process hose assemblies are engineered for use in applications where the tubing is subject to harsh chemicals, extreme temperatures or other corrosives. The tubing will not lose quality, crack or fade. The fluid inside will pass through the tube without leaching.

Many different options are available, including:

- Smooth-bore PTFE

- Rubber covered FEP lined

- Polypro-braid covered PTFE

- Stainless Steel covered PTFE

- Stainless steel braid silicone outer cover (TSC)

- We also have an extensive selection of suitable end connections to select from, including tri-clamp, ANSI flanged, cam-lock, MNPT and FNPT designs

Biopharm Silicone

Biopharmaceutical silicone tubing is manufactured to meet the demanding standards of pharmaceutical fluid processing applications. These products are designed for heat-sealed aseptic welding, eliminating the need for connectors. They are odorless, non-toxic, flexible, translucent and sterilizable. They also feature ultra-smooth, non-leaching inner surfaces.

Biopharm silicone sanitary process hoses are available in several styles, including:

- Clear

- 4-Ply wire reinforced

- Convoluted outer cove

- Nomex braid reinforced

- The available fittings we offer include electropolished tri-clamp ends and options with a 15 Ra finish

USDA Food Grade Rubber

Our tubing is made from USDA food-grade rubber meets FDA compliance standards. This material is specifically engineered to deliver the high chemical and temperature resistances needed for a wide range of food processing applications.

Food-grade sanitary flex hose is flexible, tasteless and emits no odors. It also has a natural resistance to bacteria buildup, making it easy to keep clean and safe for repeated food exposure.

We offer process tubing in a selection of food-grade polymers that includes:

- FDA Viton rubber

- FDA EPDM rubber

- FDA Buna-N rubber

- FDA Silicone rubber

Industrial Plastics

Our industrial plastic sanitary process tubing includes products made from PVC (polyvinyl chloride) and polypro (polypropylene). These materials are versatile, and we have options suited for use in many applications, including manufacturing, food processing and many other industrial scenarios.

PVC and polypro offer many advantages. These materials are both flexible, durable and provide superior longevity. Our team will help you determine which best fits into your processes to deliver the performance you need and provide you with excellent value.

Special Options

You can customize our sanitary flex hose and process hose assemblies with a number of affordable options. These include:

- Hose identification systems: We have several options available for labeling hoses and making them easier to identify. Some of our most common are adding laser-etched labels, vulcanized hose tagging, electro etching and color coding using colored hoses and braids.

- Special hose coverings: Hose coverings provide added protection for hoses subject to extreme temperatures, high pressure, excessive friction, kinking, crushing and other damaging conditions. Rubber, silicone, stainless steel and other base materials are available to match your needs.

Custom Hose Racks

Proper storage is essential if you want to keep your sanitary process hose assemblies in good condition and make them last. Our stainless steel custom hose racks provide a safe and convenient solution. These products are designed to store your hoses in accordance with the manufacturer’s recommendation and comply with FDA and 3A storage regulations.

Our racks are compact and the best way to keep your hoses, clamps and gaskets organized, off the floor and out of the way for a safer and work environment. We have multiple designs to select from, including heavy-gauge, mobile and rugged fabrications and wall-mounted racks that ensure 100% fluid drainage.

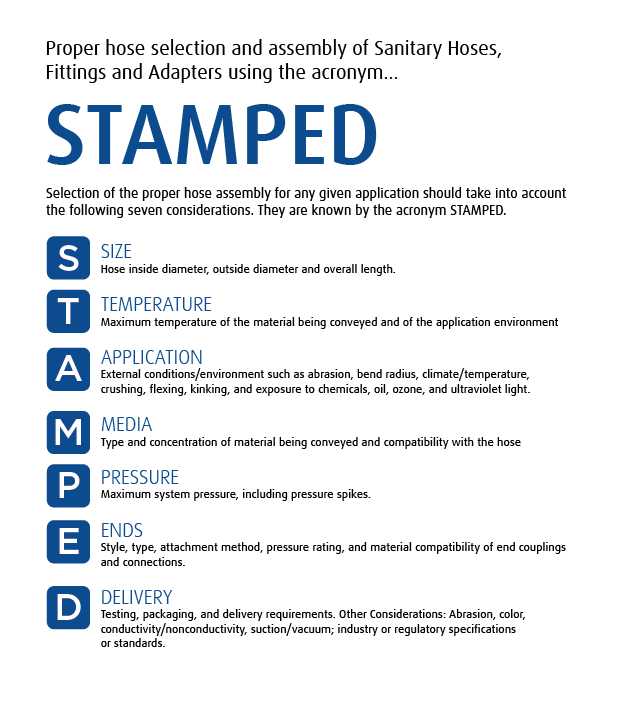

Find the Right Sanitary Flex Hose for Your Application

If you need a TFE-lined hose, talk to our team. We offer a large selection of sanitary process hose assemblies from the industry’s leading manufacturers. We also carry a wide variety of other innovative technologies and engineered solutions. You can rely on our experts for the skill, knowledge and expertise to help you select the best products and ensure you stay supplied with reliable ongoing support.

Contact us to learn more about our sanitary flex tubing, get a product recommendation or request a quote. You can reach us online or call us at 855-503-1280.