FLUID PASS THRU SYSTEMS

In Pharmaceutical and Biopharmaceutical manufacturing it is very common to store critical fluids (e.g. media, buffer) in a separate room from the actual production space. The goal is to achieve an aseptic transfer of fluids between rooms while isolating the two rooms. Preventing airflow and contamination between the two spaces is critical to ensuring sanitary conditions. Whether the fluid is stored in an unclassified area or a different class of cleanroom, getting the fluid to the production room space presents a host of issues. Running dedicated hard piping between the spaces requires significant upfront capital expense and time consuming cleaning when every run is complete. Another method is to manually transfer fluids in bags, bins or totes between rooms. The storage products need to be sanitized before entering the cleanroom and there is a risk of breakage, spillage and cross contamination. Using either method costs time, labor and resources.

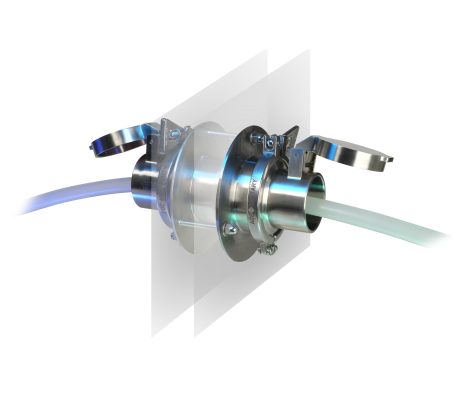

Sentinel Process Systems is pleased to offer a better alternative for aseptic transfer of fluids. SafePass Fluid Pass Thru provides a safe, reliable and economical method for transferring large volumes of fluids between rooms without dedicated hard piping or physically moving bags, bins or totes around. The use of Single-Use components eliminates the need to clean after every run and helps lower the overall cost of operations. The precision molded Clamp Gasket seals the penetration hole and the exterior surface of the customer’s Single-Use Tubing providing complete isolation between the two rooms. SafePass gives Users the freedom to use their own Single-Use Tubing in a variety of sizes. Having to replace the Clamp Gasket and Single Use Tubing after every run combined with the minimal set-up time saves Users time and money while minimizing the risk of losing product.

Key Features

- No proprietary Single-Use tube assemblies required, Customers use their preferred tubing using sizes from ¼” to 1” OD

- Clamp Gasket prevents unwanted airflow between rooms and is easy to replace

- Single or Multiport designs

- 316L Stainless Steel Housings allow easy cleanup

- Can be used in new construction or renovations and with Modular wall systems or fixed walls

- Available with Straight or Sweep connections and Sight Glass option

- Little to no maintenance

- Competitive Lead times

Downloads

MATERIAL PASS THRU SYSTEMS

Eliminating cross contamination in biomedical and pharmaceutical facilities is critical to ensuring efficient operations. With the need to physically move nonliquid product or materials between cleanroom spaces and adjacent non-sterile areas, a specialized Pass Thru system will help minimize airflow, cross contamination and depressurization. Sentinel works with several Partners to offer a wide variety of Material Pass Thru systems from a simple passive Pass Thru to a highly engineered Pass Thru to meet most every requirement.

Key Features

- Available in 304/316 Stainless Steel, Epoxy Painted Steel or Plastic

- Simple latching or electromagnetic/mechanically interlocked door systems

- Standard or custom sizes

- Passive or Active

- Solid or framed glass doors

- Wall-mount or Floor-mount

- Fire suppression capability

- Pressurized environment

- HEPA/ULPA filter option

- Wash down features with drainage that meet cGMP standards

- Manufactured in the USA

Whether it is material, rolling cart or personnel, Sentinel has the Pass Thru that will meet your need.