Dissolved Oxygen Measurement in Critical Processes

DO sensors play a central role in applications where oxygen availability influences reaction kinetics or biological performance. Common uses include fermentation, cell culture, media and buffer preparation, and oxygen-sensitive synthesis or processing steps.

A dissolved oxygen probe delivers stable, repeatable measurement that allows operators to identify subtle changes or process drifts early. This visibility supports stable operating conditions, improved batch consistency and reduced risk of unplanned deviations, which avoids unnecessary system complexity or downtime.

[See Oxygen Theory Guide]

Sensor Technologies and System Integration

Sentinel Process Systems offers dissolved oxygen sensors from METTLER TOLEDO, the leading supplier to the pharmaceutical and chemical industry.

Available solutions include electrochemical and optical dissolved oxygen sensors for operational simplicity and fast response. These sensors eliminate electrolyte handling and polarization time while maintaining accurate oxygen measurement.

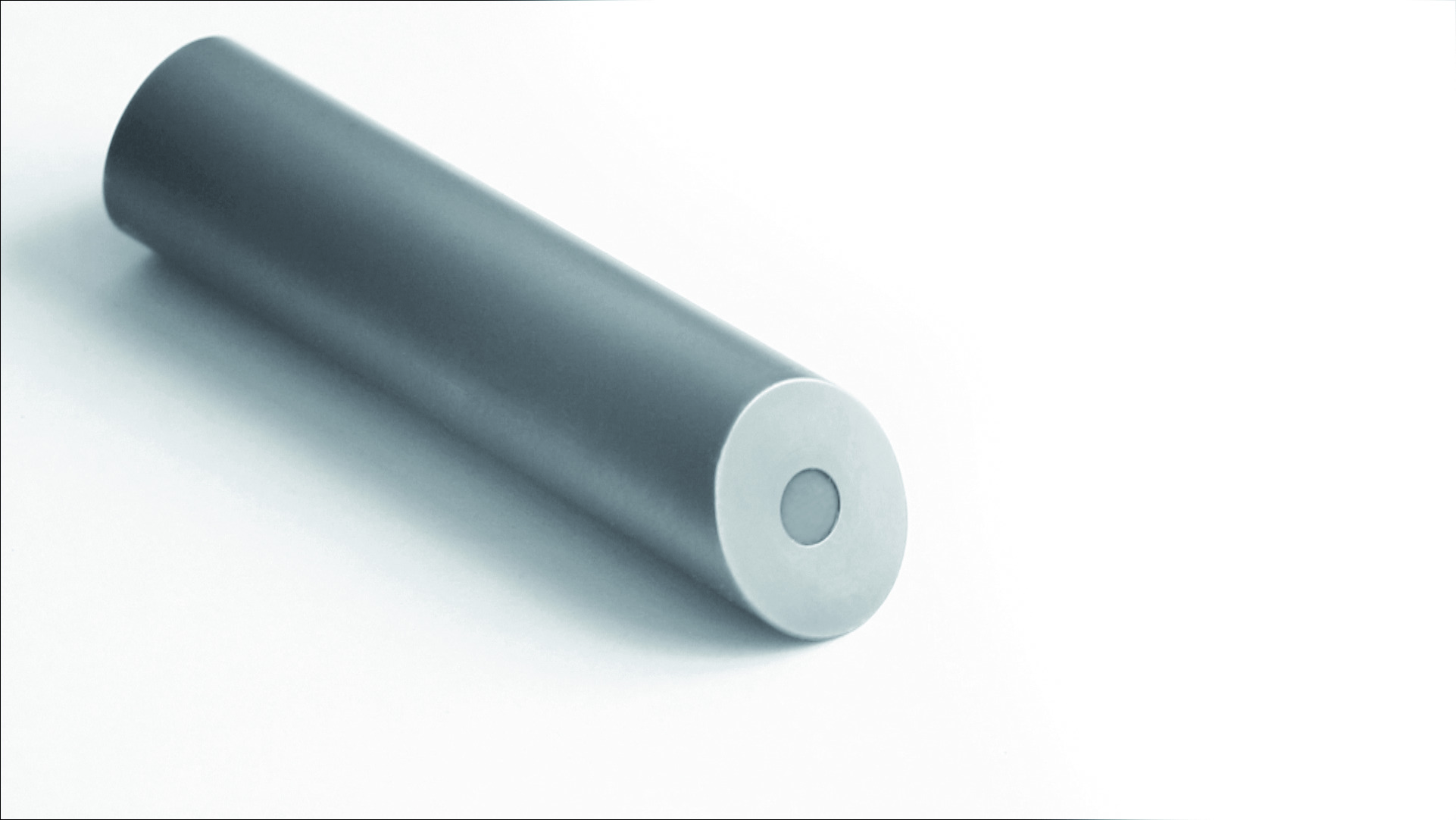

The InPro™ line provides hygienic measurement solutions, including sterilizable and autoclavable sensors designed to optimize fermentation and cell culture processes. The InPro 6860i and 6860i HD optical sensors deliver accurate dissolved oxygen measurement without electrolyte changes or polarization procedures. The 6860i HD features an angled OptiCap design that helps reduce oxygen bubble interference.

Each DO probe supports digital ISM interfaces, including Modbus RTU, as well as analog outputs for integration into existing bio controllers, transmitters and process environments, including HART-compatible systems.

Additionally, these sensors feature materials of construction compatible with high-purity fluids and repeated cleaning and sterilization cycles.

How to Select a Dissolved Oxygen Sensor

When selecting a dissolved oxygen sensor, there are multiple considerations, including performance characteristics and compatibility. Consider from the following list what’s important for your needs:

- Measurement accuracy and precision

- Mechanical durability and chemical resistance

- Response time

- Maintenance requirements

- Temperature compensation

- Calibration simplicity

- Digital connectivity and integration

- Sensor longevity

- Application versatility

- Regulatory alignment

- Resistance to fouling

Performance and Connectivity in Regulated Environments

Dissolved oxygen sensors must perform reliably under varying temperatures, pressures and flow conditions. The sensors supplied by Sentinel meet or exceed FDA and GMP requirements and are engineered for use in high-purity, validated processes. They deliver stable output that supports reproducible results during development, scale-up and routine production. Plus, the integrated temperature compensation supports accurate readings across varying operating conditions.

The Intelligent Sensor Management technology enables true plug-and-measure operation with advanced diagnostics and life-cycle monitoring. This improves installation efficiency, maintenance planning and operational safety, all while maintaining consistent performance.

Why Choose Sentinel Process Systems

We’ve provided reliable and quality products and services since 1950. Our customers work with subject matter experts who understand high-purity processes and help remove complexity from equipment selection.

Key advantages include:

- Unmatched experience of more than seven decades.

- Broad portfolio of industry-leading dissolved oxygen sensors from trusted manufacturers.

- Application-driven recommendations based on process conditions, not part numbers.

- Stocking programs that reduce lead times and support unexpected outages.

- Local technical support for faster response and issue resolution.

- Custom fabrication capabilities that complement sensor installations.