- Products

- Single-Use Tubing Solutions

- Single-Use Media Storage

- Single-Use Connectors

- Process Hose Fabrication

- Process Analytics

- Flow Control

- Filtration

- Process Valves

- Clean Steam Products

- Sealing Technologies

- Bioprocess Instrumentation

- Bioprocess Fittings and Fabrications

- Cleanroom Furnishings

- Flow Chemistry

- Reaction Support Equipment

- Services

- Manufacturers

- Resources

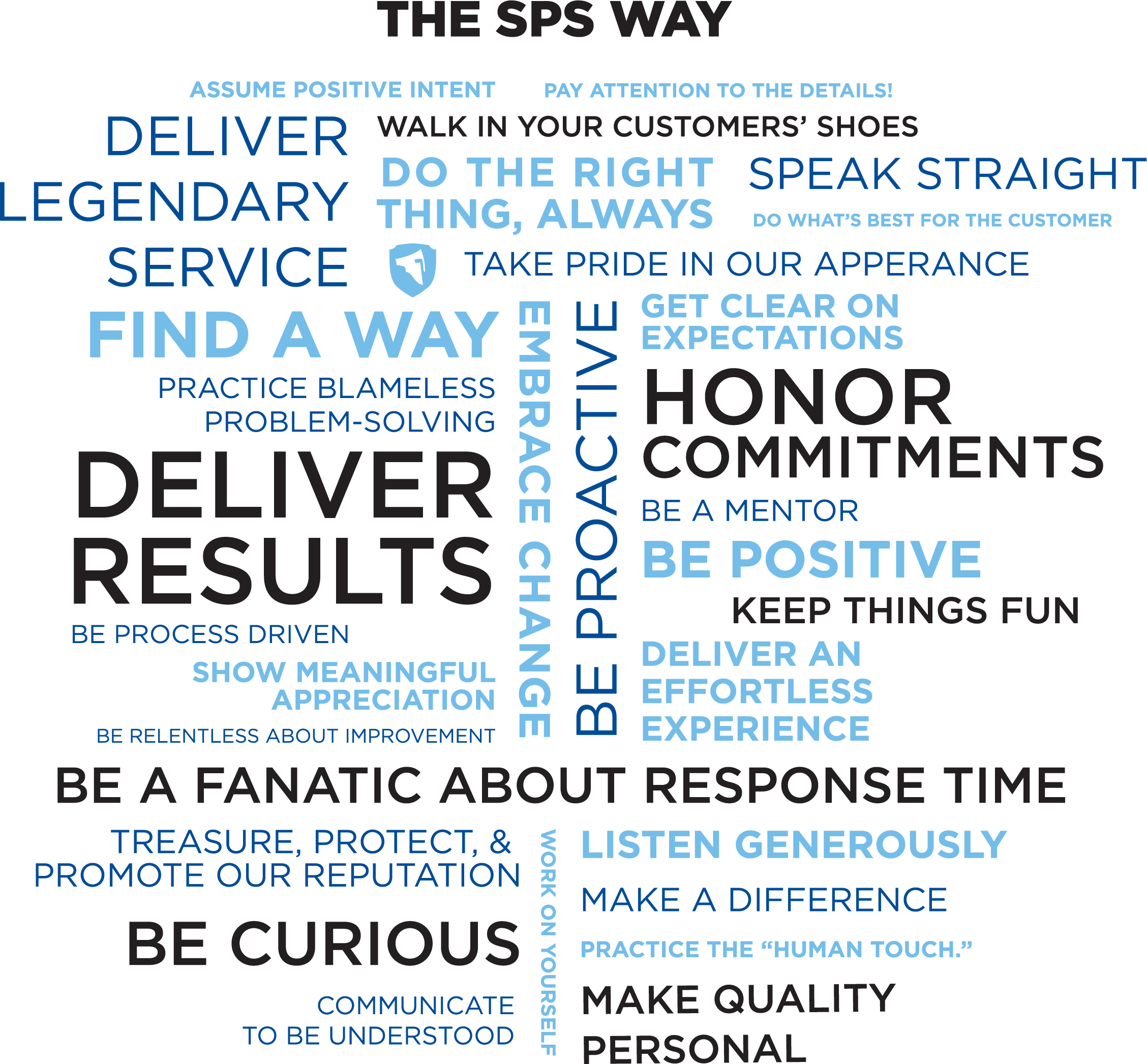

- About Us

- Contact Us