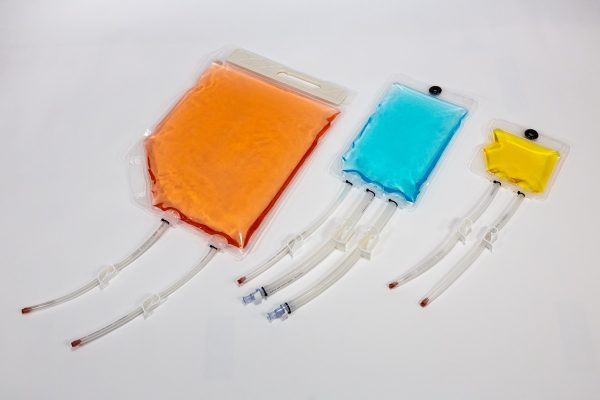

2D Bioprocess Bags

These flat, single-use storage solutions are ideal for low to medium-volume applications where a compact footprint and ease of integration into existing systems are critical. Sentinel’s 2D single-use bioprocess bags are engineered for the secure storage and transfer of sterile liquids in controlled environments.

Single-use solutions maintain material integrity throughout processing and are suitable for applications such as chromatography collection, irradiation containment, freeze/thaw applications and solution transfers to bioreactors.

They offer benefits such as:

Space-efficient design: The flat design allows for easy storage in smaller spaces.

Cost-effective solutions: 2D bioprocess bags cost less than stainless-steel alternatives while maintaining high sterility and integrity.

Customizable features: These bags can customized to fit your specific process needs, including different port configurations and volumes.

3D Bioprocess Bags

Sentinel’s customizable 3D bioprocess bags offer robust, large-volume solutions for complex single-use biopharmaceutical processes. Ideal for demanding upstream and downstream applications, 3D single-use bioprocess bags feature multi-layer films that combine exceptional strength with low gas permeability, which is crucial for maintaining product integrity.

Their tailored design significantly reduces seam usage, thus enhancing bag integrity and minimizing leakage risks. The 3D format supports applications such as high-volume storage or mixing, bulk sterile shipping, purification, chemical processing and bioreactor harvesting.

They come with benefits such as:

Large volume capacity: These bags are ideal for use in large-scale processes.

Efficient and flexible: They are perfect for integrating with existing processes, with custom design options to fit your unique needs.

Lower leak risks: Their reduced seam design eliminates 70% of seams compared to traditional configurations, significantly reducing leak risk.

Outer Containment Solutions

Sentinel’s 3D bioprocess bags can be integrated with rigid outer containment systems for applications requiring additional security. Compared to stainless-steel tanks, these rigid containment options are more cost-effective and lightweight and reduce the turnaround time between batches by eliminating complex cleaning protocols.

Design Elements That Differentiate 3D Bags From 2D Bags

While both 2D and 3D bioprocess bags offer versatile single-use solutions, the main difference lies in their design and application:

Shape and volume: 2D bags feature a pillow design used for small to medium-volume applications, whereas 3D bags are designed with more robust construction to handle larger volumes and more complex processes.

Assembly complexity: 3D bags support more elaborate tubing sets and port arrangements, often incorporating bottom drain ports and dip tubes.

Contact Us for Custom 2D and 3D Bioprocess Assemblies

Sentinel Process Systems delivers comprehensive and fully customizable 2D and 3D bioprocess assemblies that integrate with necessary components such as tubing, connectors, fittings, filters, valves and other essential accessories. Our assemblies provide biopharmaceutical companies with turnkey solutions engineered to match unique process requirements.

Key benefits of our bioprocess assemblies include:

Tailored solutions: We collaborate with you to offer custom assemblies that fit your exact process, reducing the need for additional modifications or system adjustments.

Faster lead times: Our quick turnaround times and managed stocking programs allow for faster implementation of your bioprocessing systems.

Regulatory compliance: Our assemblies meet industry standards, including full traceability and E&L testing.

Contact Sentinel Process Systems today to discuss your bioprocessing requirements.